Technical Surveys

New approaches to maintenance of electrical switchgear have been pioneered by the post-privatisation electricity supply industry. These are now finding increasing acceptance in the private sector for low voltage equipment as well as high-voltage networks.

Condition-based maintenance relies on monitoring parameters that indicate the condition of the equipment and using this to determine the appropriate time to carry out maintenance. The use of non-destructive testing to predict plant failure is well known, but it is rarely used to assist in determining plant maintenance periods. However, this has changed with improvements in the reliability of non-destructive apparatus and the accumulation of data over the years.

Where should it be used?

Condition-based maintenance is appropriate to HV equipment such as oil-filled switchgear where annual changing of the oil is unnecessary, but dissolved gases or chemicals in the oil could have disastrous effects if left undetected. It is also appropriate to mission-critical low-voltage switchgear, where it enables incipient faults to be detected so that remedial action can be scheduled for times when disruption to business will be minimal.

What are the procedures?

Oil sampling is well established for testing for evidence of corrosion or wear in oil-filled equipment. A small sample is drawn off for analysis rather than changing the oil completely.

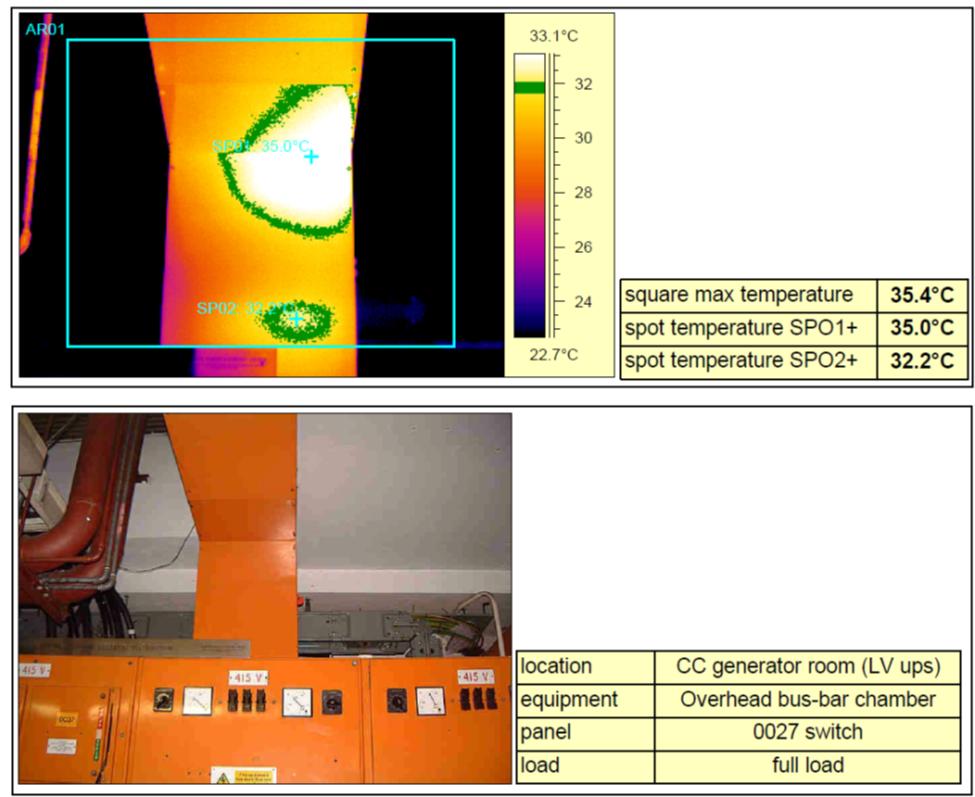

Infrared detection, or thermographic measuring, is another non-destructive procedure used to identify ‘hot spots’ caused by terminations that have worked loose or components that are overheating. The equipment is scanned by the means of a handheld thermographic camera. Some technical skill is required to interpret the results correctly – for example an undervoltage coil that is operating correctly will generate some heat and show up as a ‘hot spot’ in thermographic charts.

Partial discharge testing is a relatively recent technique that can be used to predict possible switchgear and bushing failures by sensing partial discharges in faulty equipment. This involves the permanent installation of sensing equipment within the plant so is appropriate to expensive or mission-critical equipment.

At HVUS we can offer a full range of non-intrusive, condition based maintenance along with technical surveys and

- Transformer Oil Analysis

- Partial Discharge

- Arc Flash Surveys

- Switch Health Check

- Thermographic Surveys

- Protection and Coordination Studies

Condition-based maintenance has enabled some operators to reduce the cost of switchgear maintenance by 80%, from about £650 per unit to £110 per unit, by extending the intervals between servicing of 11 kV switchgear.

Got a question?

Call us on:

01564 794 706